Sustainability:

Designed For The Long Run

Our long term thinking on sustainability through the lens of product philosophy, responsible manufacturing, and community engagement.

Our long term thinking on sustainability through the lens of product philosophy, responsible manufacturing, and community engagement.

Our obsession with design is not just about a jacket

Design is a matter of consequence. We have to think beyond the immediate goal of crafting exceptional product - we need to think about our impact on people and the planet. The urgency of the climate crisis broadens how we think about ourselves and the way we approach business.

We want to use the best materials and create the most refined and durable products possible. We want to make it easier for you to keep your gear in play. We want to empower people to find inspiration in nature, design and one another. We want to acknowledge our interdependence with one another and the living world, and that climate justice can’t be achieved without addressing global inequities, together.

Guided by design, community, science and passion, we have committed to halve our environmental footprint and grow our positive social impact. We align with the circularity principles of the Ellen MacArthur Foundation, and are pursuing circularity as part of our path to net zero.

Here is how we are going about it.

Collaborative low-carbon solutions

Arc’teryx was an early signatory to the UN Fashion Industry Charter for Climate Action (UN Fashion Charter), a member of the Outdoor Industry Association’s Climate Action Corps, a co-founder alongside the Pembina Institute of the Catalyst Business Coalition and one of the first 400 companies to set a verified Science Based Target. We are embracing the power of the collaborative to make structural change across industries, to meet the Paris Agreement targets and to scale low-carbon solutions.

Think long-term

We put our best energy into designing our gear. We build it to last and endure the most extreme conditions.

Durability and performance have been our guiding principles from the outset.

However, 65% of a garment’s environmental impact happens before you even see it – during manufacturing and sourcing. That is a problem that can be spread out across lifetimes, if the product is built to last – with timeless design, outstanding quality, dedicated durability. The most sustainable purchase is no purchase. Buying pre-loved ReGEAR™ is your next best move. If you are going to purchase something new, we want to provide the best option - quality that will perform, season after season, with a line-up of willing users once your relationship with that garment comes to an end. Every time you choose to buy nothing new, to favour durability over disposability, to care for and repair your gear, or to support resale, repurposed or upcycled offerings, you’re adding your weight to the growing shift towards circularity. ReBIRD™ is a hub of initiatives where we are bringing circularity to life

Sustainability means thinking long-term. The climate emergency requires that we act with a sense of immediacy.

Navigating the future and the now is not easy, but we are up for the challenge

- We commit to a Science-Based Carbon Target on Climate Action.

- We commit to working towards a circular economy.

- We commit to connecting with and supporting communities working to remove barriers to the outdoors.

- We commit to Fair Trade certification & improving working conditions everywhere we build products.

Despite the complexity of the global problems we confront, being design-led means problem solving – a collaborative, humble, iterative process. Each step forward builds upon the last. This is the way we generate the momentum needed to catalyze systemic change. We commit to showing up.

Product, materials, technology

Our product philosophy is the foundation of our approach to sustainability. We believe that building products to last is the most powerful lever for minimizing impact.

We maximize performance and durability in a number of ways, including building products that perform for their intended use, and selecting proven materials that endure and wear well over time. Our timeless aesthetic remains contemporary, and we stand behind our lifetime care, repair and product guarantee.

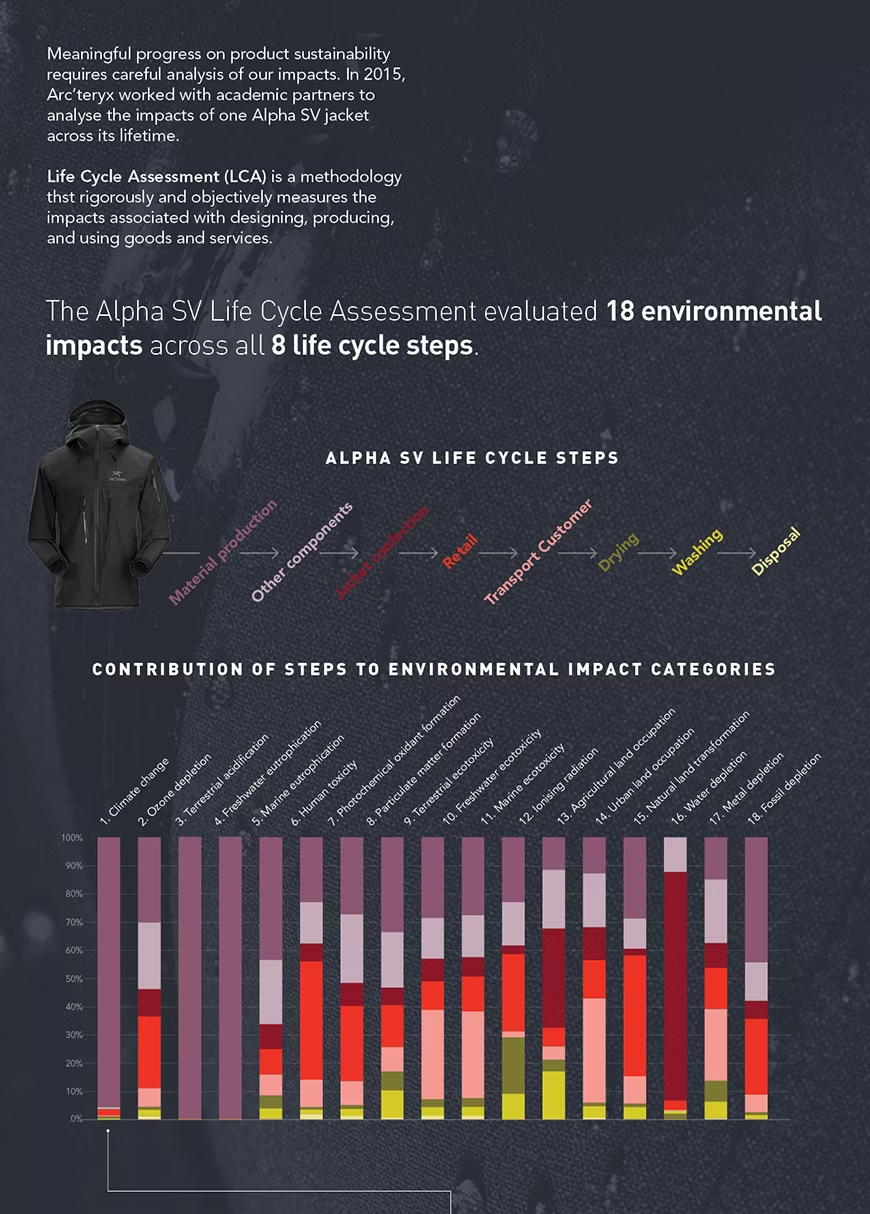

We assess products and their impacts throughout the full lifecycle. This means ongoing analysis throughout multiple steps including sourcing raw materials, garment manufacture, distribution, and retailing. It also includes use, care and repair, and ultimately end of use.

Life, Cycle Assessment (LCA) is a science-based methodology that helps us identify where impacts lie within this life cycle. It applies a rigorous protocol to measure the specific environmental effects of every single step of a product’s life. From our LCA work we have found that around 65% of the lifetime environmental impact of one of our jackets comes from the production of raw materials and the manufacture.

Using our Alpha SV Jacket as an example, the graphic below illustrates a broad range of environmental impacts throughout the steps of its lifecycle.

We view our products as systems, which require appropriate care and attention to maintain top performance over time. Proper care is one of the simplest ways to extend the life cycle of any product. Technical fabrics, waterproof membranes, and adhesives maintain their function better with regular washing and occasional retreatment. Not only does a well maintained product function better, it also lasts longer.

Information on proper care for technical products is listed in our Product Care FAQ.

Repair services also keep functional products out of landfills. Most tears and damage can be fixed. We have dedicated teams, worldwide, to help extend the life of product. For specific questions about product service, visit our Product Service FAQ.

At our Vancouver manufacturing facility alone, we repaired nearly 10,000 products in 2021 despite the challenges of COVID-19, returning cherished items to their owners for further use. If a product can't be repaired to our quality standards yet is in usable condition, we work with one of our long-term donation partners to find it a new home. Many of the programs we donate to support youth outdoor initiatives by maintaining 'lending libraries' of gear for participants.

Our goal is to source base materials that are safe for people and the environment while also ensuring top product quality and performance.

Technical outdoor fabrics and components are most often made from synthetic raw materials and rely on active chemistry to achieve their specific function, level of performance, and durability. To address the resulting impacts, we engage directly with the suppliers of the materials via a comprehensive Materials Compliance Program.

We have adopted the Bluesign® system Restricted Substances List (RSL) that outlines a broad range of materials that require careful management due to negative impacts on the environment, health, or occupational safety. We work directly with our material suppliers to ensure that we adhere to the RSL standards throughout our supply chain.

As a Bluesign® system partner we've chosen to use a third-party global textiles management system that defines safer, environmentally responsible materials to be used at each step of our supply chain. The Bluesign® system allows us to choose safer inputs to our products rather than attempting to control the outputs. This makes materials sustainability into a design input. The system's five key focus areas are: resource productivity, consumer safety, water emissions, air emissions, occupational health and safety.

PFAS stands for Per- and Polyfluoroalkyl Substances. These are a family of chemicals historically used for waterproofing in the outdoor industry. In recent years, science has highlighted a problem with PFAS: it is slow to break down, so it persists for a long time in the environment.

We’re committed to doing the right thing for people and planet, therefore, we spent years working with our partners at GORE TEX to create ePE – a waterproof membrane free of intentionally added PFAS. In our approach to design and sustainability, Arc’teryx is guided by science and fully supports the removal of PFAS from its products.

Our unwavering commitment to building the most reliable, durable and high-performance product for mountain activities meant we invested a lot of time into testing our new ePE and PFAS-compliant products including FC0 DWR to make sure they still met our exacting standards in the field as well as our labs. The majority of our products are now PFAS-compliant, with the remainder of the Arc'teryx product line transitioning in the coming months.

We use antimicrobial treatments in a range of our products to inhibit bacterial growth and prevent odours. This allows the products to last longer between washes and over time.

The most common treatment we use is called durable anti-odour (DAO), made using trace concentrations of silver salts embedded in a non-toxic polymer that binds to fabric surfaces. This treatment provides effective odour prevention and strong durability, while using minimal amounts of silver. The formulations we use are in silver salt form and are not nano silver. The larger particle size means they are not as readily taken up by organisms.

We have found that silver-based treatments like DAO are the most effective option available today that meets our standard for safety and environmental performance. Studies show that the concentrations of silver released from treated fabrics have negligible impacts on health or the environment.

We use animal-based materials in some products for their unique function. Our sourcing practices are guided through independently recognized global standards - and supplier declarations when standards are not yet available - to ensure that animal welfare is respected and the materials are traceable.

Down

We use down as an insulation material due to its exceptional warmth-to-weight ratio, compressibility, and resilience. All down used in our products is certified to the Responsible Down Standard (RDS). This independent global standard ensures animal welfare is respected and provides certification at each step of the supply chain from hatchling to final product. Live plucking and force feeding are prohibited under the RDS.

All Arc'teryx down is traceable to farms in Eastern Europe and is processed at the Allied Feather and Down facility in California. We have been sourcing from Allied since we launched down products in 2013. Allied is a fellow Bluesign® system partner, has required farm verification of animal welfare practices since 2008 and was an early implementer of third party auditing.

Wool

We use wool for its unique moisture wicking ability and next-to-skin comfort. The majority of our wool comes from ABMT in Australia and Designer Textiles in New Zealand. To ensure animal welfare is respected, our sourcing partners comply with either the ZQ Merino standard or National Wool Declaration Integrity Program. All suppliers meet our non-mulesing policy (a painful practice to manage insect pests) through either global certification or self declaration.

We are currently working to transition our wool supply to the globally recognized Responsible Wool Standard once certified RWS wool becomes available.

Leather

We use leather for its combination of durability and dexterity. Our leather suppliers comply with our Restricted Substance List, and only use leather that originates from hides that are a byproduct of the meat industry. We are also working with our suppliers to ensure that leather is sourced from Leather Working Group compliant tanneries with environmental measures in place.

Microplastic pollution is an emerging environmental concern with particular relevance to oceans and waterways. Microplastics are classified as plastic particles under 5mm in length. These particles come from a wide range of sources, including the degradation of larger plastic debris, textiles, car tires, and plastic packaging. Research shows that high concentrations of microplastic fibres are now being found in marine environments near cities, with one probable source being shedding from synthetic apparel during use and laundering.

Arc'teryx uses a range of synthetic and natural textiles in our products. We are actively working to understand the link between specific textiles and microplastic pollution. To do this we have joined a collaborative research project led by the Ocean Pollution Research Program at Ocean Wise. The project is 'fingerprinting' 30 different Arc'teryx textile samples and measuring rates of fabric shedding. Data from this research will contribute to a global library of fibre fingerprints that will help to better understand the source, transport and location of microplastics in the ocean. Our goal is to contribute to solution-oriented designs, practices and choices.

Climate action

Climate change is an urgent global crisis with immediate and intensifying impacts on communities, ecosystems, and economies worldwide. According to the Intergovernmental Panel on Climate Change (IPCC), global greenhouse gas emissions must be reduced by 43% by 2030, and reach net-zero around 2050 to limit warming to 1.5°C and avoid the most catastrophic and irreversible consequences1

Achieving this goal demands rapid, far-reaching transitions. For Arc'teryx, balancing the imperative to reduce the climate impacts of our building energy usage, material inputs, product lifecycles and supply chain processes against the pursuit of business success is one of the most complex and defining challenges of our time and calls on us to fulfill our purpose to Leave It Better.

In 2020, we set our first science-based targets to reduce our emissions intensity by 2030. We made demonstrable progress toward these initial goals, but we knew we could do more. In 2023, we went back to the drawing board and set bolder, more ambitious science-based targets focused on reducing absolute emissions rather than emissions intensity. These updated targets were submitted and verified by the Science Based Targets initiative (SBTi) in 2024, pushing us to climb farther than ever before on our route to reach net-zero.

Net Zero by 2050

Arc'teryx is committed to achieving net-zero greenhouse gas (GHG) emissions across our value chain by 2050. Our interim targets, validated by the Science Based Targets initiative2 include:

- Reducing absolute Scope 1 and 2 GHG emissions by 90% by 2030 from a 2022 base year3

- Reducing absolute Scope 3 GHG emissions by 42% by 2030 from a 2022 base year

Our climate strategy focuses on areas where we have the greatest opportunity and impact

We identify and prioritize emissions reductions where we have the greatest opportunities for impact across our business: the products we make, suppliers we work with, transportation of our products, and the buildings where we work and sell our products

- Product: Increase the percentage of preferred materials in our products and support our customers to keep their gear in use longer.

- Suppliers: We partner with our suppliers to reduce emissions in their facilities and manufacturing processes

- Transportation: Optimize our supply chain and transition to less carbon intensive modes of travel.

- Buildings: Reduce our own emissions in Arc'teryx offices, distribution centres, and stores.

- Other: Explore opportunities to reduce other emissions categories.

Achieving our net-zero target is the summit we are striving toward, and our route to get there represents a challenging but rewarding and critically important climb. Getting there will require technological innovation, collaboration with suppliers and other partners, and a global transformation to a lower carbon economy. Luckily, getting out of our comfort zone has been part of our DNA since day one, and we are ready to face the challenge. Along our route, we commit to reporting annually on our progress. Read our most recent 2024 Climate Report, 2023 Climate Report, and 2022 Climate Report. To chart our progress since the beginning, you can also check out our inaugural * 2019 Climate Report, 2020 Climate Report and 2021 Climate Report.

*Arc'teryx's inaugural reports were published in 2019, 2020, and 2021 respectively and reflect the methodologies, data availability, and assumptions applicable at that time. They are provided here for historical reference only. The information and targets described may have since been updated, superseded, or revised. Readers should not rely on these reports as reflecting our current sustainability performance, practices, or commitments. For our most recent disclosures, please see our 2024 Climate Report.

Responsible manufacturing

Responsible manufacturing means we take responsibility for the environmental and the social impacts of making our products.

Arc'teryx has been intimately connected to manufacturing since our beginning. For many years, our office and design floor were located inside our factory. Today, we continue to run our operations at our Vancouver manufacturing facility, ARC'One.This deep connection to manufacturing forms the basis of our approach to sustainability in our global supply chain.

While Canadian production represents the foundation of our manufacturing knowledge, our production is global.

Products must meet our demanding quality, so we partner with the highest performance technical apparel facilities in 10 countries to help us achieve required volumes. We stand behind every product we make, and are proud to call out the facilities behind each piece. An Arc'teryx label, no matter the place of manufacture, is an assurance of quality, durability and performance.

Our design approach, devotion to detail and quality, and our long-term relationships with manufacturing facilities create an opportunity to influence conditions for workers that we are actively leaning into.

Starting in 2020, we have begun supporting a growing list of 25 of our manufacturing facilities through the independent third-party Fair Trade Certified™ program to empower workers by providing additional funds that workers receive and that they can direct to improve their livelihoods. Products that are Fair Trade Certified provide you with the assurance that worker rights–their health and safety - are being protected. Additionally, Fair Trade premiums generate a worker-controlled Community Development Fund which the workers collectively apply to secure tangible benefits in their own lives.

To learn more about our relationships with our supply chain partners, please visit our Supply Chain Partners page.

ARC'One is an Arc’teryx-owned Canadian factory located in Greater Vancouver. Essential to our design process and product philosophy, having our own factory helps make us who we are. We have confidence in the choices behind our materials selection and construction techniques, because we understand the challenges of manufacturing first-hand. This unique position enables us to continually evolve our crafting of durable, high performance products.

The apparel manufacturing sector and workforce in Canada is shrinking by about 5% per year; however, our Canadian production capacity is increasing as we continue to invest in technical apparel and gear manufacturing in Canada. As of December 2019, ARC'One employs approximately 520 people. We have a training facility on site to teach new operators the technical skills of the trade. Local organizations ThreadWorks and Immigrant Services Society of BC (ISSofBC) offer industrial sewing programs, helping us overcome the challenges of finding new staff.

ARC'One allows us to design and prototype in unique, exclusive ways, then use that proprietary knowledge to scale production and bring our solutions to the world.

We have assembled a global network of 21 manufacturing facilities in Bangladesh, Cambodia, Canada, China, El Salvador, Indonesia, Latvia, the Philippines, and Vietnam. Each facility meets our strict standards for quality and production, adheres to clear and stringent labour practices and demonstrates a commitment to reducing environmental impact.

We seek to build long-term relationships with our partners. Many of our finished goods facilities have worked with us for 6 or more years and in some cases, 15 years. We are intentional and selective with our partner facilities, seeking out manufacturers who share an ethos of problem-solving and technical prowess. We require partners committed to a long-term relationship – it can take up to three years to build the skills to craft our most technical products. Once a new partner is identified, we spend a year training their teams on our systems, key techniques, and production basics. Another year is used to stabilize these systems and introduce specialized approaches. Finally, during the third year with a new partner, we start scaling production and consider them a full capacity vendor.

When selecting materials, our process is extensive whether we are developing materials ourselves or direct sourcing from a supplier. Throughout the design and development process, materials are tested in-house, in the lab and in the field. All of our materials are approved by us before they are sent to our manufacturing partners.

The depth of relationship with our manufacturing partners illustrates a values alignment that is foundational to who we are - sustainability is one of our core values.

COVID-19 triggered a deep inquiry into the vulnerability of workers in our supply chain and prompted a commitment to act on our values as a company.This commitment and year-long journey is documented in our blog ‘The Path is Made By Walking It’.

By 2025, 80% of Arc’teryx products will be Fair Trade Certified™. We consider this to be one small step among many that are needed to transform apparel supply chains. Fair Trade Certified is an existing mechanism to improve livelihoods.

Supply chains will need to be radically remade to prioritize worker well-being through fair wages and social protections. We commit to this larger reset.

People are at the heart of our business and make it possible to build our products. We are committed to ensuring human rights are upheld everywhere our products are made.

HUMAN RIGHTS & WORKING CONDITIONS

Fair Labour Association

Starting in June 2020, our parent company Amer Sports has been accepted as an associate member of the Fair Labour Association (FLA) which will provide our social compliance program with third-party accreditation, to ensure education, training and engagement opportunities for workers. We also take responsibility for the impact of our decisions on workers in the supply chain, building greater sustainability awareness with our upstream decision-makers on how their last minute design changes or adjustments to forecasts tangibly affect people’s working conditions. The FLA holds us to standards that demand better planning, better communication, and mitigating negative impacts to workers on the manufacturing floor. Full accreditation will take several years, requiring new ways of thinking and a restructuring of all systems to level up to these rigorous standards.

Starting in 2021, as evidence of our learning journey, we will share our FLA-approved social compliance audits of our manufacturing facilities. Revisit this page to follow our progress, as we hold ourselves to greater social responsibility in our supply chain and ultimately do better by the workers whose skills we depend on.

Higg Index: Facility Social & Labour Module (FSLM)

As part of our commitment to transparency in our supply chain, our monitoring approach is constantly evolving as we seek better ways to improve practices, and ensure we’re meeting best practice in the next tier down in our supply chain, with our raw material suppliers. In 2021, as a member of the Sustainable Apparel Coalition (SAC) we support “audit convergence” to empower the industry to move away from duplication of audits from multiple brands and allow a focus on tangible improvements. To start, in 2021 we are utilizing the Higg Index Facility Social & Labour Module (FSLM) self-assessment with more than 40 of our most important fabric suppliers. We will share updates here and on our supply chain partnerspage.

Country-Specific Approach

Some of the countries where we operate present specific challenges to human rights - we address these on a case-by-case basis. The decision to produce in each location with each partner is an area for ongoing improvement, taking into account the state of development of the local apparel sector, human rights, political, and environmental factors, as well as the relationship with our partners, and other sourcing considerations. If relevant political factors are out of our reach, we focus on what we can influence: the practices within the facilities themselves and creating jobs that have a positive impact on the skilled workforce who build our products.

Our design approach-an obsession with quality and meticulous attention to detail –combined with our valued-aligned relationships with our suppliers, create a unique opportunity to influence and improve livelihoods for workers. We are committed to continue to lean into this challenge.

WORKER EMPOWERMENT

Engaged workers bring products to life. Taking care of employees and supporting their well-being has long been a priority for our operations at home–their engagement and passion creates better products. COVID-19 revealed the need to demand this concern for all the people who work on our products–especially those beyond our immediate influence. This reckoning galvanized us. We are actively exploring all the levers available to us, and seeking out fellow problem solvers who share a desire to catalyze a massive global systems shift. One immediate response was to adopt one of the leading existing mechanisms to improve the livelihoods of workers – Fair Trade Certification. Our hope is it may be the new minimum adopted by the entire industry – a bottom line commitment to worker well-being. We build from here.

Fair Trade Certified™

The Fair Trade journey began in early 2020 when we committed our 2021 collection at three manufacturing facilities. By fall 2021, close to 60 models, or 20% of our collection, will be Fair Trade Certified. By purchasing our products as Fair Trade Certified from a certified manufacturing facility, we are ensuring working conditions and safety are in place to protect workers’ health and that additional premiums are paid for each order. Workers are empowered as a collective to decide how to spend the additional premium for themselves.

By 2025, 80% of Arc'teryx products will be Fair Trade Certified™

WHAT'S NEXT

Fair TradeCertified™ alone is not enough. We need to instill resiliency into supply chains by planning for emergencies and natural disasters, ensure sourcing decisions take into account the impact on workers,engage in multi-stakeholder dialogues like the Garment Industry Call to Action, and more.

We believe the minimum bar in our industry needs to be raised. This is not work we can do alone. We encourage and invite our industry colleagues, governments, financial institutions, and others to join this collective conversation for the benefit of the people who are the heart of our business.

This is a living commitment. We don’t have all the answers needed to immediately resolve global inequities in the apparel industry. Massive systems aren’t easily remade. Systemic change doesn’t come with a how-to manual, and requires the best efforts of many actors –consumers, brands, regulators, policy-makers all pushing towards a shared vision. As problem solvers and design thinkers, we commit to being part of this work, and we will continue to update this section as our learning and impact evolves.We welcome your support.

The majority of our environmental impact originates in our supply chain. From raw materials and textile production to product manufacturing, we create significant impact. We are in the process of developing emissions targets for all aspects of our business, based on what the science is telling us is needed. At the same time, we are helping our supply chain partners find efficiencies and reduce our impact.

We have adopted the Higg Index, which is an industry-wide voluntary tool managed by the Sustainable Apparel Coalition (SAC). The Higg Facility Environment Module (FEM) is a management and data tracking tool that allows suppliers to better understand their operations. 100% of our finished good manufacturing partners and 75% of our strategic material suppliers are actively reporting on the Higg Facility Environment Modules (FEM).

We are actively working with a number of our key strategic manufacturing partners and material suppliers to support implementation of renewable energy and energy efficiency measures. We openly collaborate with other brands to reduce the overall impacts of our entire industry, as our supply chains are often interconnected. We support initiatives like the Impact Apparel Institute, Clean by Design, Clean Energy Investment Accelerator to scale the change that the science requires. We are also assessing alternative approaches and will continue to publish updates as they evolve.

By choosing to increase production in British Columbia, which has a provincial carbon tax, we have an additional incentive to invest further in energy efficiency initiatives. ARC'One consolidated 3 locations into one new building equipped with energy efficient measures like motion sensors, lighting timers and programmable thermostats. We use the Higg Index to help us better understand where we can improve and share best practices with our manufacturing partners globally. We know we have a long road ahead to make strides in environmental and social sustainability, but at Arc’teryx, we lean into tough challenges.

Community partnerships

Our philosophy

We believe that connection to nature can be transformative. As an organization dedicated to the mountains, Arc’teryx aims to be a force for positive change. We create this change not only by improving the practices in our core operations, but by supporting projects and partners within the communities we share.

We’re grateful to partner with talented community leaders and grassroots organizations working to remove barriers, protect nature and serve the needs of global outdoor communities. We’re supporting, learning from, and following the lead of BIPOC-led, Indigenous-centering, 2SLGBTQQIA+ and women’s sports organizations as we collectively strive to advance the movement toward more equitable access to nature.

We are developing longer-term strategic partnerships with community leaders poised to change the world for the better, mapping our resources to support the vision and work of those creating systemic change in the outdoors. Through these meaningful community partnerships, we aim to center and amplify the voices of Black, Indigenous and People of the Global Majority. We are grateful for their leadership and teachings, and will continue to follow their lead in the movement toward equitable access to nature.

Arc’teryx is committed to the implementation of the Truth and Reconciliation Commission (TRC) Calls to Action and the United Nations Declaration on the Rights of Indigenous Peoples. Being guided by First Nation, Indigenous, Inuit, Métis and Tribal community we will be using a lens of truth and reconciliation throughout our business as we strive to advocate for and support, the preservation and protection of the air, lands and waters of the places we love.